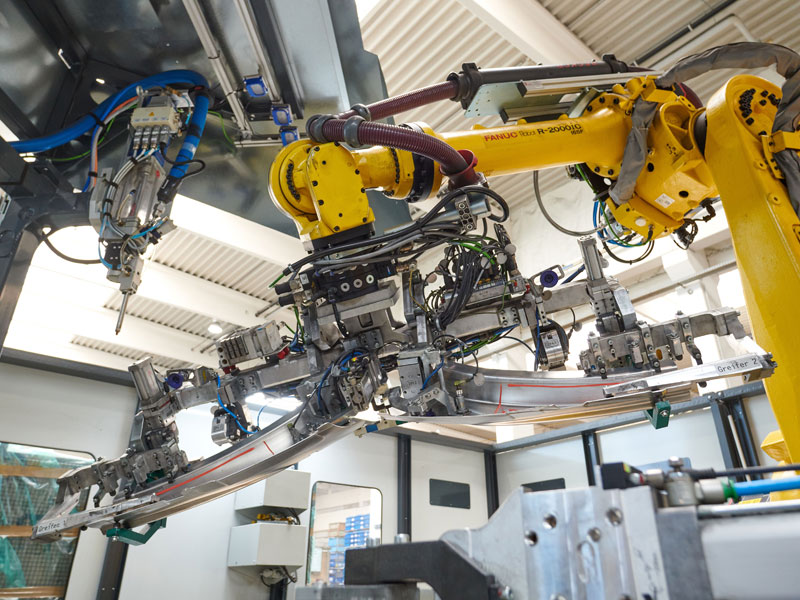

In our automated assembly centers with integrated test functions, we manufacture ready-to-install assemblies from individual components for various applications in the body. In addition to welding (inert gas, spot and hump welding), the joining technologies of brazing, gluing, riveting, screwing as well as flanging and clinching are also being used.